Working platforms

In order to provide a better protection to persons working on construction sites Part of the Construction Sites (Safety) Regulations (the Regulation) has been revamped. The amended Regulation spells out the broad principle, namely the contractor has a general duty to make and keep every place of work on construction site safety, and in particular, to take suitable and adequate steps to prevent persons from falling from a height of 2m or more. Width of working platforms, gangways and runs

▪ not less than 400 mm

▪ not less than 650 mm for gangway or run used for movement of materials

Construction of working platforms, gangways and runs

▪ closely boarded or planked (a working platform, gangway or run -

consisting of open metal work having interstices none of which exceeds 4000 mm2 ;

the boards or planks forming it are secured to prevent movement and the space between adjacent boards or planks does not exceed 25mm

▪ need not be closely boarded or planked if there is no risk of persons below it from being struck by materials or articles falling through the platform, gangway or run)

▪ boards or planks forming platforms etc.

of sound construction, adequate strength and free from patent defect

not less than 200 mm in width and not less than 25 mm in thickness or not less than 150 mm in width when the board or plank exceeds 50 mm

in thickness

not protruding beyond its end support to a distance exceeding 150 mm

rest securely and evenly on its supports

rest on at least 3 supports

Coverings for opening

▪ so constructed as to prevent the fall of persons, materials, and articles

▪ clearly and boldly marked to show its purpose or securely fixed in position Height of toe boards not less than 200 mm in height (toe-boards are not required for stairs)

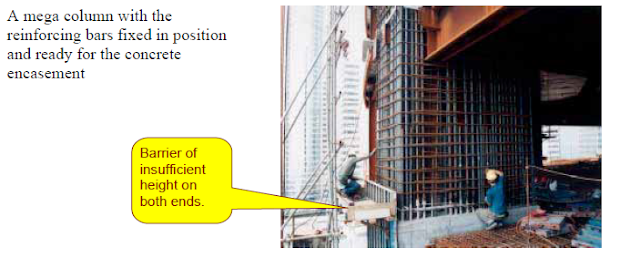

Height of guardrails the height of a guardrail above any place of work on

a working platform, gangway, run or stairway shall be

▪ top guardrail: not less than 900 mm and not more than 1150 mm

▪ Intermediate guardrail: not less than 450 mm and not more than 600 mm

For working platforms on bamboo scaffolds, these height dimensions may not apply if the platforms are protected by not less than 2 horizontal bamboo

members spaced at intervals between 750mm to 900 mm.

General safety hints for platforms and scaffolds:

▪ Provide safe access to and egress from all platforms.

▪ Keep all work platforms free from load, such as construction wastes.

▪ Suitably place platforms on sound bases, such as scaffolds, to prevent displacements.

▪ Prevent movement or tipping, especially surface dirt of platforms.

▪ Erect and dismantle scaffolds and platforms only under the supervision of a competent person.

▪ Each scaffold must be capable of supporting the load intended.

▪ The competent person must inspect scaffolds before each use.

▪ Use sound base plates to level or stabilize the footings.

Planking

▪ Closely plank a scaffold to provide a safe working platform. The working platform decking must be free from patent defects.

▪ Extend planks or decking material sufficiently over the edges or cleat them to prevent displacement. Avoid overextending the platform beyond the end

Supports to prevent tipping when workers are stepping or working on it.

▪ Avoid overextending the platform beyond the end supports to prevent tipping when workers are stepping or working on it.

▪ Be sure that working platforms are of a proper size and, for metal scaffolds, end hooks are available and attached to the scaffold frame.

Guardrails

▪ All working platforms should be safe, with a standard guardrail practical for the job. Otherwise, use other fall protection devices such as safety harnesses with lanyards and safety nets.

▪ All guardrails should be provided with a mid rail.

▪ Toeboards on the standard working platform are also required.

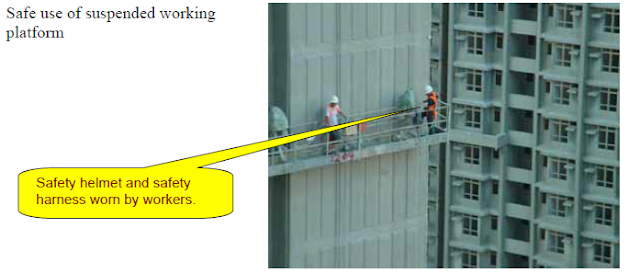

Suspended working platforms

Suspended working platforms, also commonly known as gondolas are widely used in Hong Kong. They carry workers, site personnel and engineers for working at height during the installation of curtain walls and windows, window cleaning, external renovation and decoration of buildings, bridges, chimneys, silos and other structures. The safety of workers working on suspended working platforms depends very much on whether there is a safe system of work, thorough examination, and weekly inspection. Common causes of accidents include tilting of the platform caused by poor maintenance, poor work practices, or operating under adverse weather conditions. Since most workers wear safety harness as required by law, fatal cases have been reduced in the past few years.

For detailed statutory requirements, it is useful to refer to the Code of Practice issued by the Commissioner for Labour. It provides practical guidance to the owner of a suspended working platform for compliance with the requirements under the provisions of the Factories and Industrial Undertakings (Suspended Working Platforms) Regulation.

Material Hoist

Apart from working platforms and bamboo scaffoldings, material hoist was one of the three major sources of fatal site accidents resulting from fall of a person from the height.

Material hoist is a plant commonly used on construction sites for material

transportation. In the past, most accidents were attributable to the misinterpreting or misunderstanding of the instructions or signals between the users and the operators of hoists. A common accident scenario was that the platform/skip of a hoist suddenly moved while loading or unloading was in progress. That caused the worker using the hoist to fall into the hoistway arising from loss of body balance at an unfenced edge, or being trapped by the moving part of the hoist.

In recent years, tremendous effort has been made in improving the use of equipment. The most common device currently in use is a set of interlocking landing gates. The design concept is to equip each hoistway gate with the interlocking device such that the hoist is operable only when all gates are kept closed. However, past experience had shown that certain hoistway gates were not installed with any interlocking device; or where a hoistway gate had been equipped with an interlocking device, the design and installation of the device was vulnerable to external interference. The most common one was jamming of the interlocking device thereby defeating the purpose of keeping all gates closed before the hoist could operate. For maintenance and repair projects, these problems are very often being overlooked. For some minor scale maintenance jobs, local made makeshift material hoists without any safety considerations should be discouraged. A special guide “Interlocking device on hoistway gates” published by the Labor Department outlines the technical details for their installations.

Safety training and communication to the frontline workers are essential in the

management of material hoist. Site management should plan and design at the

initial stage before any material hoist is installed. Detail specifications and method statement should be incorporated. After the erection, the equipment should be regularly inspected and maintained by competent persons. Competent persons should pay special attention to alterations and additions, e.g. deterioration of fencing at the loading and unloading points, erection of additional lifting appliance/gears such as Chicago boom, etc.

Temporary works

Temporary works is used to support a permanent structure while it is not

Self-supporting, such as commonly used in-situ concrete, precast units, and steelwork, or commonly known as “falsework”. Any failure of falsework may lead to the collapse of the permanent structure. This could cause injury or death to those working on or near to it, as well as loss of time and cost. Locally, falsework is commonly used in building construction, maintenance and Refurbishment works. A falsework that collapses during dismantling or erection can bury workers amidst the wooden formwork and uncured cement.

The cause of such accidents could be due to one or a combination of the following:

▪ no approved or calculated drawings,

▪ The drawings were not carefully prepared, such as neglecting the weather

conditions or wind effects of the site, vibration caused by other construction

operations nearby and ground conditions,

▪ the falsework was not erected by a competent person,

▪ erection or dismantling was not supervised by a competent person,

▪ the falsework was not checked by a competent person before being used,

▪ the falsework was illegally altered,

▪ overload of the falsework by unintended loads or unauthorized jobs by other

subcontractors,

▪ the falsework was not regularly checked and maintained,

▪ no safe system of work

No comments:

Post a Comment