Definitions

• Excavation – a man-made cut, cavity, trench, or depression formed by earth removal.

• Trench – a narrow excavation. The depth is greater than the width but not wider than 15 feet.

• Shield - a structure able to withstand a cave-in and protect employees.

• Shoring - a structure that supports the sides of an excavation and protects against cave-ins.

• Sloping - a technique that employs a specific angle of incline on the sides of the excavation. The angle varies based on an assessment of impacting site factors.

Focus on Training

• The greatest risk at an excavation

• How to protect employees from cave-ins

• The role of a competent person at an excavation site

Protection of Employees

- Employees should be protected from cave-ins by using an adequately designed protective system. Protective systems must be able to resist all expected loads to the system

- Requirements for Protective Systems

A well-designed protective system

Correct design of sloping and benching systems.Ø

Correct design of support systems, shield systems, and other protective systemsØ

Appropriate handling of materials and equipment + Attention to correct installation and removal = Protection of employees at excavations

Design of Protective Systems

The employer shall select and construct :

slopes and configurations of sloping and benching systems.Ø

support systems, shield systems, and other protective systems.Ø

• Shield - can be permanent or portable. Also known as trench box or trench shield.

• Shoring - such as a metal hydraulic, mechanical or timber shoring system that supports the sides.

• Sloping - from sides of an excavation that are inclined away from the excavation.

Protect Employees Exposed to Potential Cave-ins

• Slope or bench the sides of the excavation.

• Support the sides of the excavation, or

• Place a shield on the side of the excavation and the work area

Cave-in Hazard

This excavation has inadequate support posts and egress access

Inadequate Protective System.

This worker is in a trench with no protective system, that is not sloped or benched and has no means of egress

Factors Involved in Designing a Protective System

• Soil classification

• Depth of cut

• Water content of soil

• Changes due to weather and climate

Shoring

• General

Provides a framework to work in Uses wales, cross braces and uprights Supports excavation walls

• OSHA

- Must know soil type

- Must know depth and width of excavation

- Must be familiar with the OSHA Tables

Trench Shield

A trench shield was built around this work area

Hydraulic Trench Support

• Using hydraulic jacks the operator can easily drop the system into the hole

• Trench pins are installed in case of hydraulic failure

Materials and Equipment

• Equipment used for protective systems must not have damage or defects that impair function.

• If equipment is damaged, the competent person must examine it to see if it is suitable for continued use.

• If not suitable, remove it from service until a professional engineer approves it for use

Protection from Vehicles

• Install barricades

• Hand/mechanical signals

• Stop logs

• Grade soil away from excavation

• Fence or barricade trenches left overnight

Hazardous Conditions

The weight and vibrations of the crane make this a very hazardous condition.

Spoils

• Don’t place spoils within 2 feet from edge of excavation

• Measure from nearest part of the spoil to the excavation edge

• Place spoils so rainwater runs away from the excavation

• Place spoil well away from the excavation

Other Excavation Hazards

• Water accumulation

• Oxygen deficiency

• Toxic fumes

• Access/Egress

• Falls

• Mobile equipment

Water is Hazardous

When water is present in an excavation it is extremely hazardous to enter

(NB: These workers are not wearing hardhats to protect them from materials falling into the trench)

Water = Cave-in Hazard

These workers must be protected from a cave-in. Note the water in the bottom of the trench. This is a very hazardous condition!

Hazardous Atmosphere

Test excavations more than 4 feet before an employee enter the excavation for:

Ø Oxygen deficiency

Ø High combustible gas concentration

Ø High levels of other hazardous substances

Means of Egress

A stairway, ladder, or ramp must be present in excavations that are 4 or more feet deep, and within 25 feet of the employees.

Ø The ladder should extend 3 feet above the excavation.

Ø This ladder does not meet the requirements of the standard

Access and Egress

These two ladders which are lashed together are not an adequate means of egress

The ladder should extend 3 feet above the top of the excavation

Protection from Falls, Falling Loads, and Mobile Equipment

• Install barricades

• Use hand / mechanical signals

• Grade soil away from excavation

• Fence or barricade trenches left overnight

• Use a flagger when signs, signals, and barricades are not enough protection

Competent Person

Must have had specific training in and be knowledgeable about:

• Soils classification

• The use of protective systems

• The requirements of the standard

Must be capable of identifying hazards, and authorized to immediately eliminate hazards

Inspections of Excavations

A competent person must make daily inspections of excavations, areas around them and protective systems:

• Before work starts and as needed,

• After rainstorms, high winds or another occurrence which may increase hazards, and

• When you can reasonably anticipate an employee will be exposed to hazards.

• If the competent person finds evidence of a possible cave-in, indications of failure of

protective systems, hazardous atmospheres, or other hazardous conditions:

• Exposed employees must be removed from the hazardous area

• Employees may not return until the necessary precautions have been taken

Site Evaluation Planning

Before beginning excavation:

Ø Evaluate soil conditions

Ø Construct protective systems

Ø Test for low oxygen, hazardous fumes, and toxic gases

Ø Provide safe in and out access

Ø Contact utilities

Ø Determine the safety equipment needed

Summary

• The greatest risk in an excavation is a cave-in.

• Employees can be protected by sloping, shielding, and shoring the excavation.

• A competent person is responsible to inspect the excavation.

• Other excavation hazards include water accumulation, oxygen deficiency, toxic fumes, falls, and mobile equipment.

Overview of OSHA Standard

Cave-ins are perhaps the most feared trenching hazard. But, other potentially fatal hazards exist, including asphyxiation due to lack of oxygen in a confined space, inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities.

OSHA requires that workers in trenches and excavation be protected and that safety and health programs address the variety of hazards they face.

The OSHA standards intend to protect workers in excavations and trenches. Basically, these standards require that walls and faces of all excavations in which workers are potentially exposed to danger from moving ground be guarded by a shoring system, safe sloping of the ground, or equivalent means of protections such as trench shields or boxes. However, the standards are applicable only to trenches 5 feet or more in depth.The standards apply to all open excavations made in the earth’s surface, Which includes trenches.

OSHA defines a trench as narrow excavations made below the surface of the ground in which the depth is greater than the width not exceeding 15 feet. An excavation is any man-made cut, cavity trench or depression in the earth’s surface formed by earth removal.This can include excavations for anything from cellars to highways.

CONSTRUCTION INDUSTRY REGULATIONS

The Occupational Safety and Health Administration issued its first excavation and trenching standard in 1971 to protect workers from excavation hazards. (Cave-ins).

OSHA's revised rule applies to all open excavations made in the earth's surface, which include trenches.

Definitions:

Benching: A method of protecting employees from cave-ins by excavating the sides of an excavation to form one or series of horizontal levels or steps, usually with vertical or near vertical surfaces between levels.

Cave-In The separation of a mass of soil or rock materials from the side of an excavation, or the loss of soil from under a trench shield or support system, and its sudden movement into the excavation, either by falling or sliding, in sufficient quantity so that it could entrap, bury, or otherwise injure and immobilize a person.

Competent

Person One who is capable of identifying existing and predictable hazards in the surroundings or working conditions, which are unsanitary, hazardous, or dangerous to employees, and who has the authorization to take prompt corrective measures to eliminate them.

Excavation Any man-made cut, trench, or depression in an earth surface, formed by earth removal.

Trench A narrow excavation below the surface of the ground, less than 15 feet wide, with a depth no greater than the width.

Protective System A method of protecting employees from cave-ins, from a material that could fall or roll from an excavation, or from the collapse of the adjacent structure. Protective systems include support systems, sloping and benching systems, shield systems, and other systems that provide the necessary protection.

Shield A structure that is capable of withstanding the forces imposed on it by a cave-in and thereby protects employees within the structure. Shields can be permanent structures or can be designed to be portable and moved along as work progresses.

Sloping A method of protecting workers from cave-ins by excavating to form sides of an excavation that are inclined away from the excavation to prevent cave-ins. The angle of incline required to prevent a cave-in varies with differences such as soil type, length of exposure, and application of surcharge loads.

General Requirements:

1- The following specific site conditions should be taken into accounts for safe excavations:

a- Traffic

b- Nearness of structure and their conditions

c- Soil

d- Surface and groundwater - the water table

e- Overhead and underground utilities

f- Weather

2- Before any excavation actually begins, the standard requires the employer to determine the estimated location of utility installations: Sewer, telephone, fuel, electric, water lines or any other underground installations that may be encountered during digging.

3- No employee should operate a piece of equipment without first being properly trained to handle it and fully alerted to its potential hazards.

4- The standard requires that a competent person inspect, on a daily basis, excavations and the adjacent areas for possible cave-ins, failures of protective systems and equipment, hazardous atmospheres, or other hazardous conditions.

5- Adequate protective systems will be utilized to protect employees. This can be accomplished through sloping, shoring, or shielding.

6- Workers must be supplied with and wear any personal protective equipment deemed necessary to assure their protection.

7- All spoil piles will be stored a minimum of two (2) feet from the sides of the excavation. The spoil pile must not block the safe means of egress.

8- If a trench or excavation is 4 feet or deeper, stairways, ramps, or ladders will be used as a safe means of access and egress. For trenches, the employee must not have to travel any more than 25 feet of lateral travel to reach the stairway, ramp, or ladder.

9- No employee will work in an excavation where water is accumulating unless adequate measures are used to protect the employees.

10- A competent person will inspect all excavations and trenches daily, prior to employee exposure or entry, and after any rainfall, soil change, or any other time needed during the shift. The competent person must take prompt measures to eliminate any and all hazards.

11- Excavations and trenches 4 feet or deeper that have the potential for toxic substances or hazardous atmospheres will be tested at least daily. If the atmosphere is inadequate, protective systems will be utilized.

12- If work is in or around traffic, employees must be supplied with and wear orange reflective vests. Signs and barricades must be utilized to ensure the safety of employees, vehicular traffic, and pedestrians.

Soil Classification and Identification

The OSHA standards define soil classifications within the simplified soil classification systems, which consist of four categories:

a- Stable Rock

b- Type A Soil

c- Type B Soil

d- Type C Soil

Stability is greatest in stable rock and decreases through type A and B to type C, which is the least stable.

Stable Rock: is defined as natural solid mineral matter that can be excavated with vertical sides and remain intact while exposed. (Example: granite or sandstone).

Type A Soil: are cohesive soils with the unconfined compressive strength of 1.5 tons per square foot or greater. (Example: clay, silty clay, sandy clay, clay loam)

Type B Soil: are cohesive soils with an unconfined compressive strength greater than 0.5 tons per square foot but less than 1.5 (tsf) (Example: angular gravel, silt, silt loam)

Type C Soil: are cohesive soils with an unconfined compressive strength of 0.5 tsf or less.(Example: gravel, sand and loamy sand, submerged soil, soil from which water is freely seeping.

Soil Test & Identification:

Many kinds of equipment and methods are used to determine the type of soil prevailing in an area, as described below:

Ø Pocket Penetrometer: Penetrometers are direct - reading, spring - operated instruments used to determine the unconfined compressive strength of saturated cohesive soils. Once pushed into the soil, an indicator sleeve displays the reading.

Ø Visual Test: If the excavated soil is in clumps, it is cohesive. If it breaks up easily, not staying in clumps, it is granular.

Ø Thumb Penetration Test: The thumb penetration procedure involves an attempt to press the thumb firmly into the soil in question. If the thumb makes an indentation in the soil only with great difficulty, the soil probably types A. If the thumb penetrates no further than the length of the thumbnail, it is probably Type B soil, and if the thumb penetrates the full length of the thumb it is type C.

Ø Dry Strength Test: Try to crumble the sample in your hands with your fingers. If it crumbles into grains, it is granular. Clay will not crumble into grains, only into smaller chunks.

Ø Wet Manual Test: Wet your fingers and work the soil between them. Clay is a slick paste when wet, meaning it is cohesive. If the clump falls apart in grains, it is granular.

Excavation Protection Systems:

There are three basic protective systems for an excavation and trenches:

a- Sloping and Benching Systems

b- Shoring Systems

c- Shields Systems

The protective systems shall have the capacity to resist without failure all loads that are intended or could reasonably be expected to be applied to or transmitted to the system.

1. Sloping and Benching Systems:

Ø Sloping Systems:

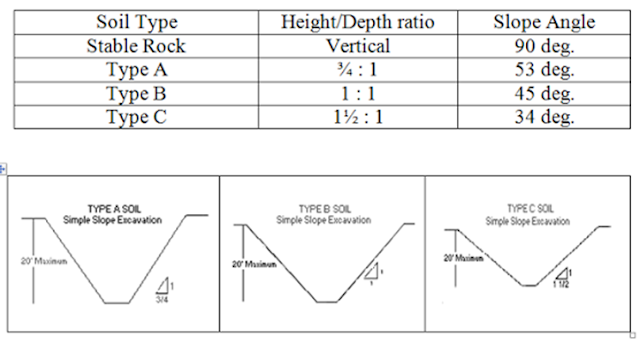

Maximum allowable slopes for excavations less than 20 feet (6.09 m) based on soil type and angle to the horizontal are as follows:

Benching Systems:

There are two types of benching, simple and multiple. The type of soil determines the horizontal to vertical ratio of the benched side.

As a general rule, the bottom vertical height of the trench must not exceed 4 feet (1.2 m) for the first bench. Subsequent benches may be up to a maximum of 5 feet (1.5 m) vertical in Type A soil and 4 feet (1.2 m) in Type B soil to a total trench depth of 20 feet (6.0 m).

2- Shoring Systems:

Shoring is the provision of a support system for trench faces used to prevent movement of soil, underground utilities, roadways, and foundations. Shoring is used when the location or depth of the cut makes sloping back to the maximum allowable slope impractical. Shoring systems consist of posts, wales, struts, and sheeting. There are two basic types of sharing, timber and aluminum hydraulic.

A- Hydraulic Shoring:

Hydraulic Shoring is a prefabricated strut and/or wale system manufactured of aluminum or steel. Hydraulic shoring provide a critical safety advantage over timber shoring because workers do not have to enter the trench to install or remove hydraulic shoring.

All shoring should be installed from the top down and removed from bottom up.

B- Pneumatic Shoring:

Works in a manner similar to hydraulic shoring. The primary difference is that pneumatic shoring uses air pressure in place of hydraulic pressure. A disadvantage to the use of pneumatic shoring is that an air compressor must be on site.

3- Shielding Systems:

A- Trench Boxes:

Are different from shoring because, instead of shoring up or otherwise supporting the trench face, they are intended primarily to protect workers from cave-ins and similar incidents. The space between the outside of the trench box and the face of the trench should be as small as possible. The space between the trench boxes the excavation side are backfilled to prevent lateral movement of the box.

B- Combined Use:

Trench boxes are generally used in open areas, but they also may be used in combination with sloping and benching.

The box should extend at least 18 inch (0.45 m) above the surrounding area if there is sloping toward excavation. This can be accomplished by providing a benched areas adjacent to the box.

H- Spoil:

Temporary spoil must be placed no closer than 2 ft. (0.61 m) from the surface edge of the excavation

No comments:

Post a Comment